This DIY Split-Flap Sign Will Get Anyone's Attention

from hackster.io

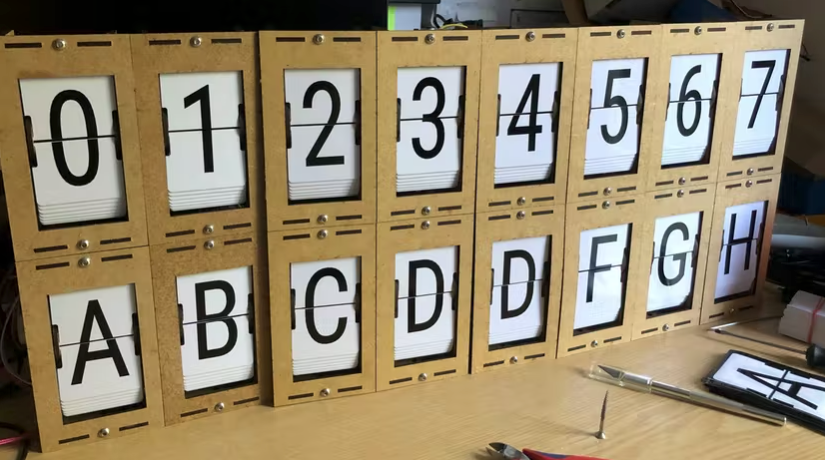

The one common feature found in an alarm clock from the 1970s and older train depot displays is "split-flap" characters. As a way to recreate their eye- and ear-catching display, Erich Styger on the MCU on Eclipse blog demonstrates a sign using 20 hand-built characters.

What are split-flaps? These mechanical displays have a character made from two pieces mounted on a wheel. As a wheel turns, the pieces "flip" into place. While not required, a stepper motor can accurately turn the flaps to the desired position.

Styger's starting point for this project was work published by Scott Bezek. Bezek's project has extensive 3D models and design files for split-flaps available with an open source design.

There are only a few minor differences between Styeger's and Bezek's mechanical designs. For example, a 3D-printed bracket combines character modules, making them stackable.

In Styger's build notes, there is an extensive explanation of building the flaps using PVC "cards" and a CNC machine. The video comparing the sound difference between aluminum and PVC makes it clear that plastic flaps are the correct choice!

Styger developed two carrier boards that control four flap modules. The only functional difference between the two is the microcontroller targets: a tinyK22 and an LPC485-BRK. Both boards feature an NXP microcontroller with an Arm Cortex-M0+ and M4F, respectively.

The boards run from a 12V supply and have four JST connectors for the split-flap modules. An RS-485 bus connects multiple flap controllers with a theoretical maximum of 512 flap modules. Of course, power distribution becomes an issue as this design scales up. Styger admits the 4-module per MCU only works well on a smaller scale.

"Currently there is one MCU needed for 4 split-flaps: this is fine for the class environment, but for larger displays an overkill." — Erich Styger

See this MCU on Eclipse blog post with Styger's detailed build instructions for more information.

Also, check out the Scott Bezek repo, which was the foundation for this project. And finally, the Bezek Labs store on Tindie has some split-flap products available.

Leave a comment